DEM-based virtual experimental blast furnace: A quasi-steady

state model

Q. F. Hou,1* D. Y. E,1 S. B. Kuang,1

Z. Y. Li,1 and A. B. Yu1,2*

Corresponding authors, Email: qinfu.hou@monash.edu (QFH) and

aibing.yu@monash.edu (ABY).

1Laboratory for Simulation and Modelling of

Particulate Systems, Department of Chemical Engineering, Monash University,

Clayton, VIC 3800, Australia

2Centre for Simulation and Modelling of

Particulate Systems, Southeast University - Monash University Joint Research

Institute, Suzhou 215123, PR China

http://www.sciencedirect.com/science/article/pii/S0032591016308853

Abstract

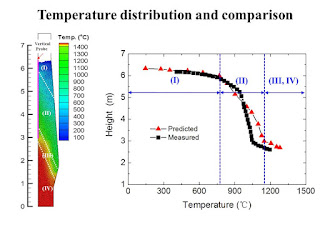

Intensive

heat and mass transfer between continuum fluids and discrete particulate

materials is quite common in many chemical processes. To understand and improve

the operation of these processes, discrete particle models are very helpful

when they are combined with the flow, heat transfer and chemical reaction

models. Here, a quasi-steady state model for investigating thermo-chemical

behaviors is established and tested for an experimental blast furnace (BF).

First, the new treatments and assumptions are discussed in detail. Then, the

model is tested against available experimental data under comparable conditions

in terms of in-furnace flow state, temperature distribution, and the

characteristics of the cohesive zone. Finally, a discussion of further

development is presented. Such a model can be used to study the effects of

burden distribution, inlet gas composition and material properties on the

operation and energy efficiency of a BF. Such particle scale modeling can be

extended to other chemical processes such as fluidized beds and rotary kilns

not only for better fundamental understanding but also for better process

design and control.

Keywords: Blast furnace,

Heat and mass transfer, Chemical reaction, Discrete element method,

Computational fluid dynamics

No comments:

Post a Comment